In November of 2016, clients from Belgium visited E.P and negotiated 70 tons/h

coal briquette production line.

According to client’s needs, the single coal briquette could resist 80-120 kgf pressure, the clients visited our lab and believed that we had strict quality control for each product.

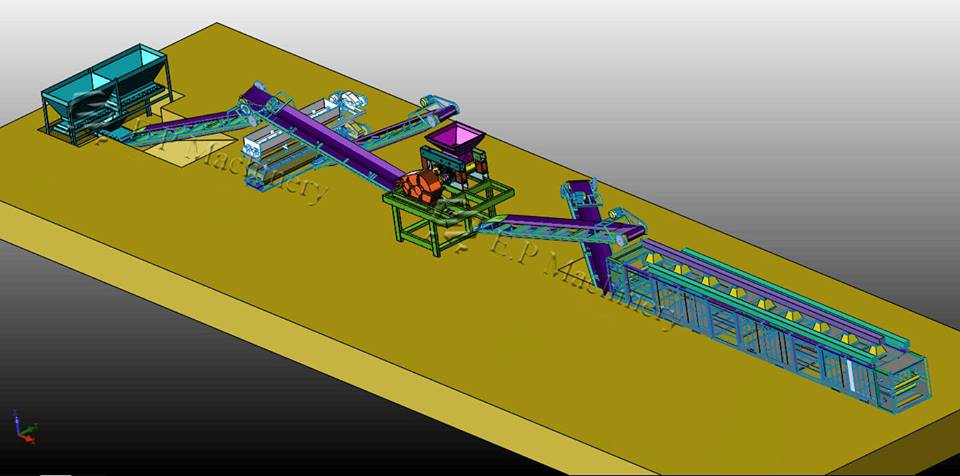

The production line drawing made by our engineer, it included proportioning, briquetting, drying system and conveying systems.

Proportioning system is to instore and feed the materials and binders at a certain ratio, it consists of two hoppers with electrical adjusted-speed feeder to control the flow speed.

Mixing system is to use three sets

twin shaft mixers to blend the mixtures.

Briquetting system is to use two sets HSYQH-1000*650 briquette press to reach 70 tons/h capacity.

Drying system adopts chain plate dryer to dry the finished coal briquettes, it is with good drying efficiency and reliable performance.