Location: Ghana, Africa

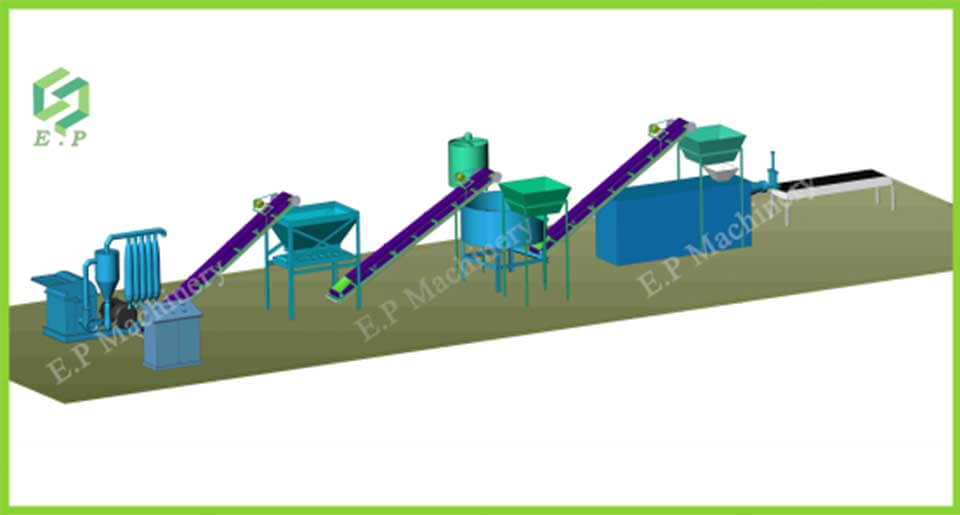

Project name: charcoal briquette production line

Capacity: 3 t/h

Applicable raw material: wood charcoal, binder is necessary.

Purpose: For making BBQ charcoal briquettes

Project introduction:

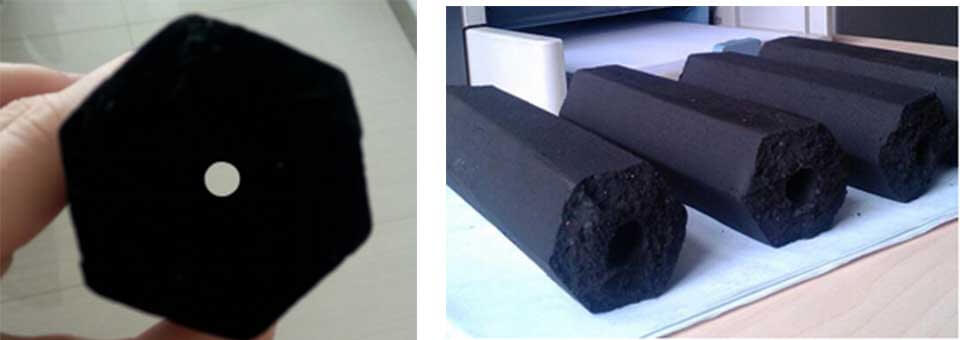

The client require to make 50mm hexagonal cylinder shape charcoal briquettes with 70mm length. The local voltage is 380V, 50HZ, 3phase. E.P team designed the

charcoal briquette production line based on his raw material information and requirements. For the charcoal briquette extruder, we designed two molding systems and automatic cutting systems, which ensure the high density, high output and good-looking appearance for the final charcoal briquettes. So, the nice briquettes would have a good sales in the market.

Processes:

Charcoal Crusher - Belt Conveyor - Dosing Hopper - Belt Conveyor - Wheel

Mixer - Charcoal Briquette Extruder - Horizontal conveyor

Main machine pictures show:

Finished briquettes: