On 25

th, June, 2018, the customers who were from Indonesia visited our company. 5 people in total, CEO, CFO, COO and technical advisers included. The project is a complete charcoal plant for making shisha cubes 25*25*25mm and BBQ charcoal, capacity 1ton/h, raw material is coconut shell charcoal.

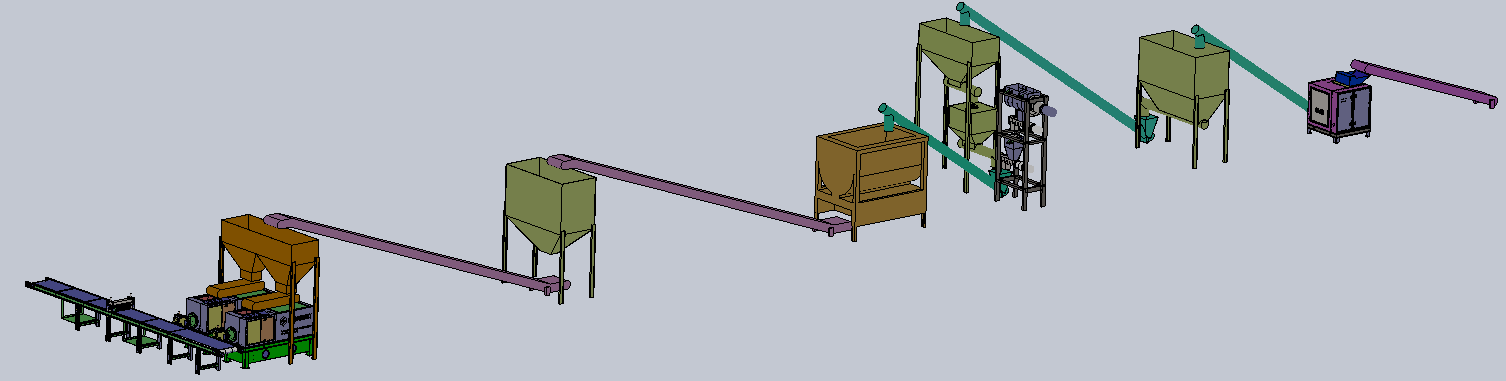

In view of the fact that the customer required 2 kinds of final products, both shisha cubes and hexagonal charcoal. We proposed extruding type line, the whole process: Crushing – Weighing – Mixing – Distributing – Shaping – Drying - Packing

The customers tested our machines in factory, including Charcoal Crusher

, Automated Weighing Hopper

, Charcoal Mixer,

Charcoal Briquette Extruder, Buffering Hopper and other auxiliary equipments. After testing for all day, the clients were very satisfied with our equipments, not only the performance of machines, but also the professional skills we provided with. The customers told us, the quality of equipments conforms to their requirements, and the BBQ charcoal and shisha cubes produced by our equipments are in accord with their markets.

After testing machines and negotiating about the whole process of line, customers asked us to go to their hotel the next day, to negotiate about contract. After negotiating about all details, including discount, special painting, delivery time, installation, etc, we signed the contract finally. Hope the customers can make excellent profits using our equipments, and keep a long-term cooperation with our company.