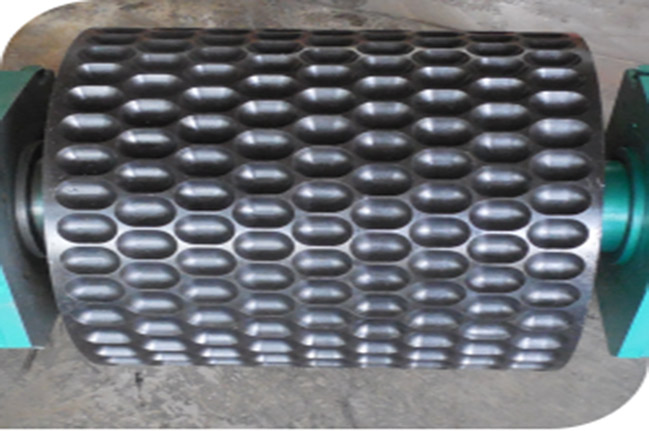

In the process of fluorite powder pressing, the most important part is formed roller, which is easy to break. Little crack in the roller will result in replacing a new one. Then how can we avoid the damage of the roller? In the production process of the

fluorite powder ball press, it is necessary to pay attention to the following points:

1. Ensure the raw material is not doped with any impurities (such as iron filings, nails, hard metal objects). If economic condition allows, a drum screen can be used to screen the materials. Another way is to install metal detection system, disperse the impurities in advance.

2. Whether the roller is of good metal alloy material or not, also affects its lifetime. Good materials can extend the utilization time of components.

3. Before leaving work everyday, check whether the roller is loose. If the roller is deviated, or not correspond, then you need to stop the machine and readjust the roller before operate again.

E.P Machinery specializes in the production of

roller compactor,

biomass briquette machines, force mixer,

dustless charcoal grinding machine,

charcoal extruder machine,

shisha charcoal briquette machine etc.