All kinds of charcoal can be used as raw materials for hookah charcoal, but generally customers will choose the following raw materials to make high-quality hookah charcoal, such as coconut shell charcoal, rice husk charcoal, palm shell charcoal, hardwood charcoal, fruit charcoal, bamboo charcoal, etc. These charcoals have the characteristics of high carbon content, good color, and few impurities, so the hookah charcoal balls made from them are also very popular in the market.

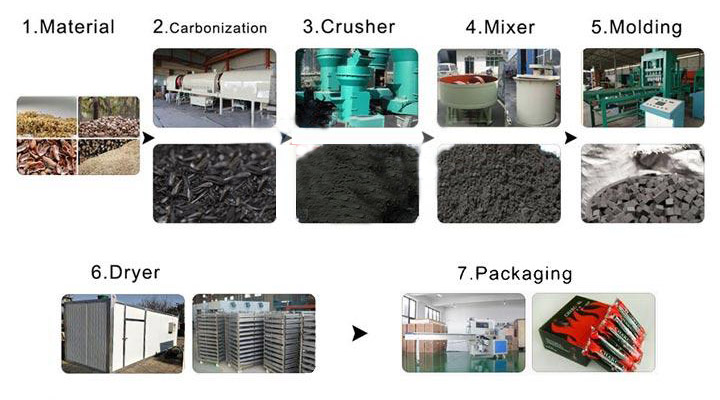

A complete production process of the hookah charcoal production line has the following steps: carbonization → crushing → mixing → tableting → drying → packaging.

Generally speaking, the production process of hookah charcoal involves carbonization furnace, hammer mill, charcoal grinding mixer, hookah charcoal tableting machine, dryer, packaging machine and other equipment.

Hookah charcoal briquetting machine

Hookah charcoal briquetting machine is suitable for making charcoal powder into small round pieces. The charcoal balls produced have high density, perfect shape, beautiful appearance, easy to burn, no odor, and long burning time. After changing the mold, the charcoal balls can be changed into cubes, cuboids, circles, etc.

Charcoal sheets or charcoal powder sheets with a diameter of 30-40mm are one of the hot-selling charcoal products in the international market. They are round, one side is convex and the other side is concave. The diameter is generally 30/40mm and the thickness is about 30mm. After changing the mold, the hookah charcoal briquetting machine can press the charcoal powder into square, cuboid, ring, triangle or pyramid-shaped pieces (Ф6-Ф40mm).

If you want to make high-quality hookah charcoal, you must first understand the characteristics of high-quality hookah charcoal. According to the survey, the high-quality charcoal briquettes in the eyes of Arabs have the following characteristics:

In order to meet the above conditions, first of all, you must choose good raw materials. For example, coconut shell charcoal. Secondly, the selection and ratio of adhesives in the production process are also very important. Finally, the higher the tonnage of the charcoal briquette machine, the better. For specific plans, please contact us to get the details of the plan.

The hookah charcoal briquette production line is a promising business for many customers engaged in charcoal production. Therefore, this is a project with a high return rate. Welcome to contact us for consultation, and we will give you the most suitable plan.

CONTACT US

+8613673361755/+8613633713237

Shenglongjinzhonghuan Building, Zhongyuan District Zhengzhou City, Henan Province, China.