As a traditional way of smoking, hookah has a wide audience in many regions. As an important part of hookah combustion, the quality of hookah charcoal directly affects the taste and use experience of hookah. Therefore, making high-quality hookah charcoal has important practical significance.

(I) Charcoal powder

High-quality charcoal powder is the basis for making high-quality hookah charcoal. Charcoal powder with high carbon content, low ash content and no odor when burning should be selected. Generally speaking, wood charcoal powder is a more ideal choice, such as coconut shell charcoal powder, bamboo charcoal powder, etc. These charcoal powders have good combustion and adsorption properties, and can provide stable heat and pure smoke for hookah.

(II) Adhesive

The function of the adhesive is to bond the charcoal powder together to form a solid charcoal block. When selecting an adhesive, its bonding strength, high temperature resistance and safety to the human body should be considered. At present, commonly used adhesives include natural substances such as starch and cellulose, as well as some environmentally friendly synthetic adhesives.

(III) Additives

In order to improve the combustion performance and stability of hookah charcoal, some appropriate additives can be added. For example, adding some combustion aids can make hookah charcoal easier to ignite; adding some moisture-proof agents can prevent hookah charcoal from getting damp during storage and use.

(I) Mixing

Mix the charcoal powder, adhesive and additives in a certain proportion. The uniformity of mixing directly affects the quality of hookah charcoal. Mechanical stirring or manual stirring can be used to mix to ensure that all raw materials are fully mixed and uniform.

(II) Molding

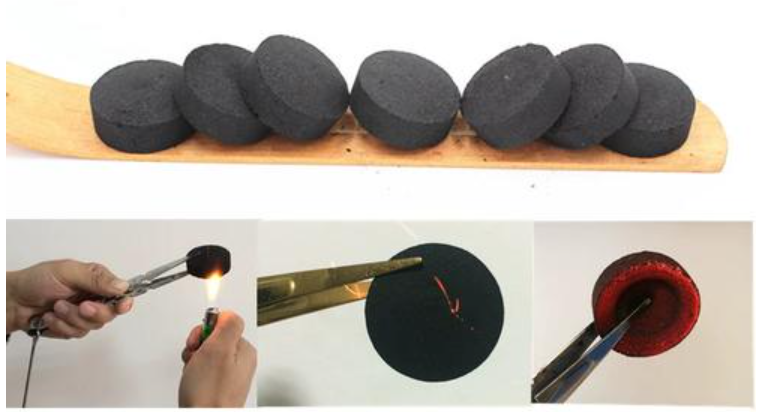

Put the mixed raw materials into the molding mold and make the desired shape of charcoal blocks by pressure molding. The size of the molding pressure should be adjusted according to the nature of the raw materials and the size of the charcoal blocks to ensure that the density and strength of the charcoal blocks are moderate.

(III) Drying

The molded hookah charcoal contains a certain amount of moisture and needs to be dried. The drying method can be natural drying or oven drying. Natural drying takes a long time, but the cost is low; drying can shorten the drying time, but it consumes a certain amount of energy. During the drying process, the temperature and humidity should be controlled to prevent the hookah charcoal from cracking or deforming due to excessive drying.

(IV) Carbonization

The dried hookah charcoal needs to be carbonized to improve its combustion performance and stability. The temperature and time of carbonization should be adjusted according to the properties of the raw materials and the size of the charcoal block. Generally speaking, the carbonization temperature is between 600℃-800℃, and the carbonization time ranges from several hours to dozens of hours.

(I) Appearance inspection

The appearance of the prepared hookah charcoal is inspected to ensure that the shape of the charcoal block is regular, the surface is smooth, and there are no cracks or damage.

(II) Combustion performance test

Through the combustion test, check the indicators such as the burning time, burning temperature, smoke volume and smoke quality of the hookah charcoal. The burning time should be moderate, the burning temperature should be stable, the smoke volume should be sufficient, and the smoke quality should be pure and odorless.

(III) Chemical composition analysis

Analyze the chemical composition of hookah charcoal to ensure that its carbon content, ash content, volatile matter and other indicators meet the relevant standards. At the same time, it is also necessary to test whether the hookah charcoal contains harmful substances, such as heavy metals, benzopyrene, etc.

The production of high-quality hookah charcoal requires the selection of raw materials, optimization of production processes and quality control. Only by selecting high-quality raw materials, adopting scientific and reasonable production processes, and strictly controlling quality can high-quality hookah charcoal with good combustion performance, high stability, pure smoke and no odor be produced. At the same time, as people's attention to health and environmental protection continues to increase, the future production of hookah charcoal should also develop in a more environmentally friendly and safe direction.

CONTACT US

+8613673361755/+8613633713237

Shenglongjinzhonghuan Building, Zhongyuan District Zhengzhou City, Henan Province, China.